Stacker Cranes + Shuttles System Makes Cold Chain Logistics Smarter

In recent years, the cold chain logistics industry has developed rapidly, and the demand for intelligent cold chain warehousing has continued to expand. Various related enterprises and government platforms have built automated warehouses.

The Hangzhou Development Zone cold storage project invested by Nanjing Inform Storage has been put into operation. The project includes cold storage, fresh-keeping storage, constant temperature storage, general bonded storage and supporting facilities, and adopts automatic intelligent storage equipment. Provide intelligent cold chain warehousing and intelligent cold chain operation suitable for one-stop imported food logistics centers for frozen, refrigerated logistics warehousing, processing, and distribution.

1. Project Overview

- CNY 300 million

- 12,000 tons

- 8,000 tons

- 30846.82 square meters (46.27 Mu)

- 38,000 square meters

- 660 tons of goods

- 12,000 tons

- 144,000 tons a yea

This project is located in the cross-border e-commerce park of Hangzhou Economic Development Zone, serving the needs of imported fresh, meat and aquatic products in the surrounding area. The total investment of the project is about CNY 300 million, and the total construction scale is a low-temperature cold storage warehouse with a storage capacity of 12,000 tons and a refrigerated storage warehouse with a storage capacity of 8,000 tons. It covers an area of 30846.82 square meters (46.27 Mu), with a plot ratio of 1.85 and a construction area of 38,000 square meters. It has one-stop logistics service functions such as quarantine, inspection, bonded, freezing and refrigerated storage, processing and distribution. The inspection warehouse that can inspect 660 tons of goods at the same time and the storage cold storage with a storage capacity of nearly 12,000 tons can meet the business volume of imported meat of 144,000 tons a year.

- Three cold storages & one room temperature storage

- 16,422 cargo spaces & 8,138 cargo spaces

- 10 lanes & 4 lanes

- 7 stacker cranes & 4 stack cranes

- 4 radio shuttles & 4 stack cranes

- Inbound and outbound conveying equipment

- 180 pallet/hour (in + out) & 156 pallet/hour (in + out)

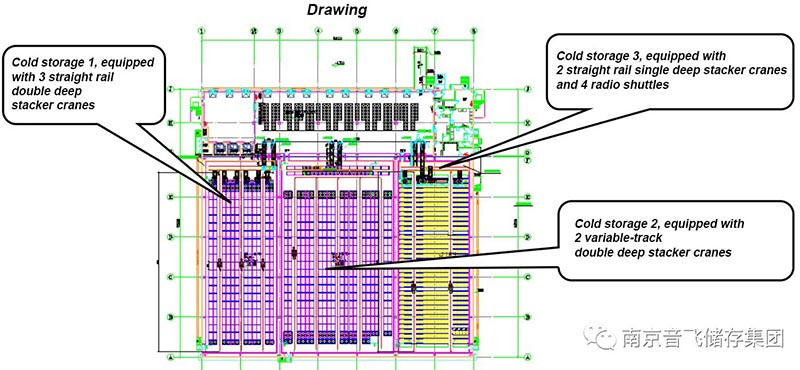

This project is divided into three cold storages and one normal temperature storage:

The total planning of the three cold storages is 16,422 cargo spaces. Through 10 lanes, 7 stacker cranes (including 2 track-change double-deep stacker cranes), 4 radio shuttles and inbound and outbound conveying equipment, the automatic in-out function is realized. The composite operation efficiency of the three warehouses exceeds 180 pallet/hour (in + out)

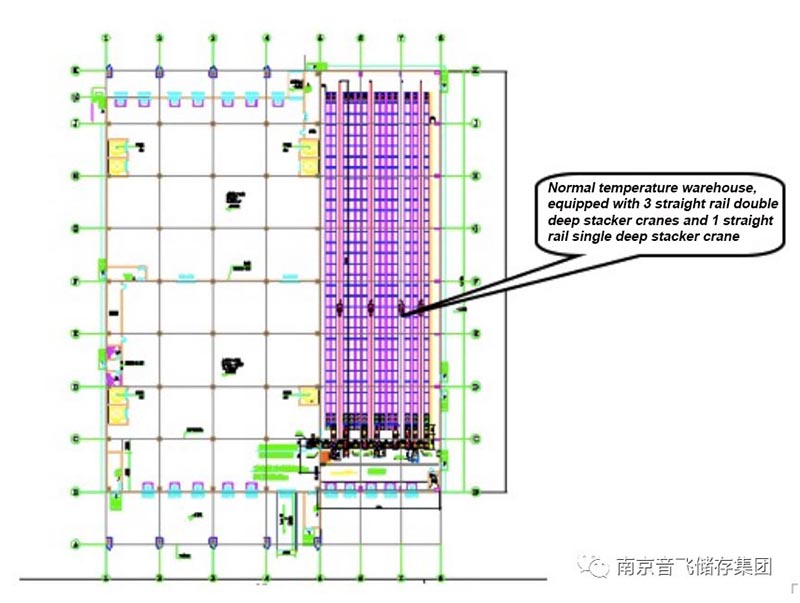

Normal temperature warehouse: The plan has a total planning of 8,138 cargo spaces. Through 4 lanes, 4 stack cranes and inbound and outbound conveying equipment, the automatic inbound and outbound function is realized. Compound operation efficiency 156 pallet/hour (in + out)

Pallet labels all use barcodes for information management. Before warehousing, it is equipped with external dimension detection and weighing to ensure the safe warehousing of goods.

Cold storage layout:

Normal temperature warehouse layout:

2. Stacker Crane + Shuttle System

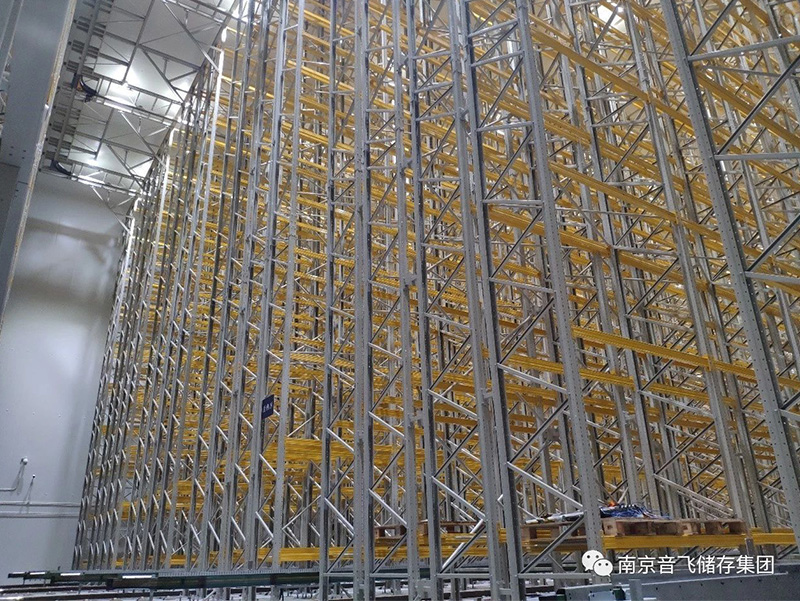

The automatic dense warehouse in the form of stacker crane+ shuttle takes advantage of the characteristics that the stacker crane runs in the front and rear and up and down directions of the main lane, and the shuttle runs in the sub lane. The two equipments are coordinated through the WCS software to complete the picking and placing of goods.

Main working principle:

Inbound: The products after automatic stacking are sent to the storage area of the automated warehouse through the conveyor line; the pallets are taken by the stacker crane and placed at the end of the roadway allocated by the WMS software; the goods are transported to the other end of the roadway by the radio shuttle. The same batch of products are stored in the same aisle.

Outbound: The shuttle moves the designated goods to the port of the sub-aisle, and the stacker crane takes the goods through the forks, places them on the outbound conveyor line, and takes them out by forklifts or other handling equipment for delivery.

Function introduction of stacker crane + shuttle system:

Receipt - can accept various materials, semi-finished products from suppliers or production workshops;

Inventory - the storage of unloaded goods in the locations specified by the automated system;

Pick-up - obtain the goods required by the customer from the warehouse according to the demand, often using a first-in, first-out (FIFO) method;

Delivery - will take out the goods to the customer as required;

Information query - can query the relevant information of the warehouse at any time, including inventory information, operation information and other information.

3. Project Benefits

Stacker crane + Shuttle Automated Intensive Storage:

① Fully automated processes can be implemented to improve work efficiency and greatly reduce working time;

② Good safety, reduce forklift collisions;

③ High-density storage, warehouse utilization rate is greatly improved than roadway stacker cranes;

④ High cost performance, the cost of unit storage position system is lower than roadway stacker crane warehouse;

⑤ The operation method is flexible.

The application of the technology of intelligent shuttle in the field of automated warehouses, through the combination of intelligent shuttle system and intensive racking, greatly improves the space utilization rate of storage facilities and saves land.

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +86 25 52726370

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: sale@informrack.com