ROBOTECH Provides Optimal Solutions for Smart Logistics in Petrochemical Industry

On July 29, the 2022 (Second) China Petrochemical Storage and Storage Tank Industry Technology Conference hosted by the China Petroleum and Petrochemical Engineering Research Association was grandly held in Chongqing. As a well-known enterprise rooted in the global smart logistics market, ROBOTECH was invited to attend the conference with its rich application experience in the petrochemical industry.

Entering the “14th Five-Year Plan” period, our country’s petrochemical industry has ushered in a critical period of transformation, upgrading and high-quality development. As an important part of the transformation and upgrading of petrochemical enterprises, the intelligent upgrading and development of warehousing and logistics is an inevitable trend.

In the sub-forum on the digital construction of petrochemical high-end warehousing and logistics technology and equipment, Liao Huaya, sales director of South China Region, delivered a keynote speech on “ROBOTECH Intelligent Logistics Robot “Dialogue” Petrochemical Intelligent Manufacturing. Introduced the warehousing features and AS/RS solutions of the petrochemical industry to the participants, and shared the successful experience of ROBOTECH in the industry.

Based on the particularity of the petrochemical industry, its warehousing and logistics system mainly has the following characteristics:

1. Long storage period and large stock

The storage period of petrochemical products varies from 10 to 20 days, which also means that the storage system of the petrochemical industry requires greater storage capacity.

2. 7×24 hours continuous operation

The petrochemical industry is a continuous process industry with the characteristics of 7×24 hours of continuous operation, which requires high reliability of the logistics system. The warehousing system is the last link of continuous production. If the equipment failure causes the production reduction and production stoppage of the upstream equipment, it will have a huge impact.

3. Large in and out” large-scale in and out warehouse

The petrochemical products in and out of the warehouse are all of the “Large in and out” type, with obvious peaks and troughs. The requirements for the operation efficiency of the storage system are relatively high.

4. The upstream and downstream are closely connected

Petrochemical products are mostly raw materials, with various brands but basically no difference in product packaging. The cross-stacking of multiple brands of products makes it more difficult to deal with the already low efficiency and high error rate of manual management.

The AS/RS solution created by ROBOTECH for the pain points of warehousing in the industry covers an intelligent logistics system covering the whole process of packaging, palletizing, wrapping, warehousing, storage, and warehousing. Record palletized product information in the packaging and palletizing process through OCR+RFID induction identification technology. The warehousing software system WMS/WCS manages the interconnection of automation equipment to realize real-time monitoring of the whole process, providing a systematic and better solution for the industry.

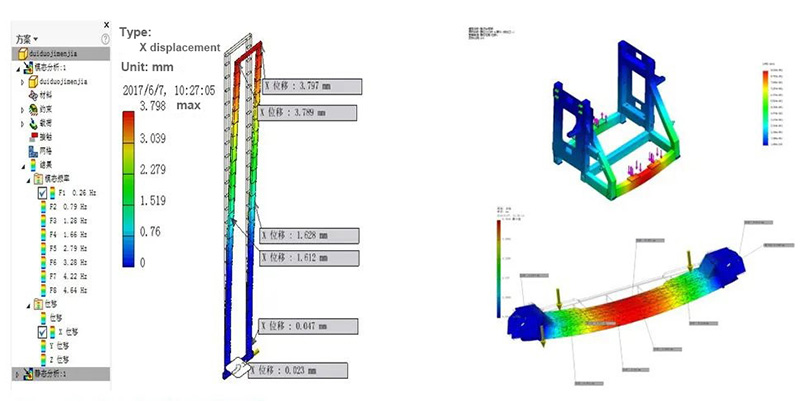

According to the characteristics of high product load and high cargo size in the petrochemical industry, the Giraffe (Giraffe) series stacker crane equipment from ROBOTECH perfectly matches this demand, with excellent structural design and strict manufacturing precision. The installation height can be up to 46 meters, and the load can be up to 2000kg. In order to ensure the high reliability and high stability of the equipment. In the design stage, the simulation of Solidworks is used for finite element analysis to ensure that the strength and rigidity of key components meet the requirements; In the operation stage, the S-curve speed control method is used to reduce the shaking degree of the column at the end of the equipment walking, and effectively ensure the safe and stable picking and placing of petrochemical products.

In the future, ROBOTECH will continue to deepen the petrochemical industry. By building an automated warehouse and breaking the silos of upstream and downstream equipment information, it will realize the intelligent operation of the whole process, help petrochemical enterprises to upgrade their warehousing and logistics intelligence, and shape their competitiveness.

In the future, ROBOTECH will continue to deepen the petrochemical industry. By building an automated warehouse and breaking the silos of upstream and downstream equipment information, it will realize the intelligent operation of the whole process, help petrochemical enterprises to upgrade their warehousing and logistics intelligence, and shape their competitiveness.

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +86 25 52726370

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: sale@informrack.com