- Home

- News

- How does the Automated Warehouse Helps the Garment Industry to Improve Storage Utilization?

How does the Automated Warehouse Helps the Garment Industry to Improve Storage Utilization?

In recent years, the development of the garment Industry has ushered in the trend of customization, C2M, fast fashion, new business models, and new supply chain service systems. As a leading enterprise of logistics equipment, Inform Storage closely follows the development trend of the industry and has recently successfully provided Anta Shoes and Daqian Textile with solutions in line with the customer’s supply chain system.

Anta Group’s integrated industrial park logistics project

Project Overview

Anta Group’s integrated industrial park logistics project has recently officially signed a contract with Inform. Inform provides intelligent automated warehouse solutions for the Anta logistics park project to create an optimized Anta footwear and apparel logistics supply chain system.

• The total number of goods in this project is about 200,000

• The warehouse area covers an area of 98,550 square meters

• It adopts a variety of shelf types such as automated AS/RS racking, VNA racking, multi-tier shelving, and panel shelves

• Warehouse utilization increased by 200%

Customer introduction

Anta (China) Co., Ltd. has now become one of the largest comprehensive sporting goods brand companies in China, and was successfully listed in Hong Kong in 2007. The product range covers clothing, shoes and accessories, and in 2008, it launched a children’s sporting goods series and a fashion shoe series. Anta has an extensive marketing network in China, covering 31 provinces, municipalities and autonomous regions, including first-, second-, third- and fourth-tier cities. Up to now, it has more than 8,000 Anta brand franchised retail outlets. Overseas, Anta products have entered 20 countries and regions including Serbia and Hungary in Eastern Europe, Singapore and the Philippines in Southeast Asia, Kuwait in the Middle East, Paraguay and Peru in South America.

Project Introduction

Anta Group’s integrated industrial park logistics project is located in Jinjiang, a model city in the footwear and garment industry. The project can support Anta Group’s business scale of over 50 billion yuan in the future, and the annual shipment of shoes and apparel will exceed 200 million pieces; Total warehouse direct distribution will cover more than 10,000 stores nationwide; The daily processing capacity of e-commerce exceeds one million orders; logistics has transformed from a wholesale model to a direct distribution model, and the product arrival time can be shortened from 35 days to the fastest 48 hours. The Inform intelligent warehouse solution helps Anta Group realize the intelligent and automated construction of the logistics industry in the process of industrial transformation and upgrading, effectively reducing costs and improving the competitiveness of products.

Ningbo Daqian Textile cotton yarn warehouse project

Project Overview

Ningbo Daqian Textile Co., Ltd. recently signed an official cooperation agreement with Inform, and Inform provides an intelligent automated storage solution for the cotton yarn warehouse project of Ningbo Daqian Textile Co., Ltd.

• The total number of goods in this project is about 16880

• The warehouse covers an area of more than 7,000 square meters

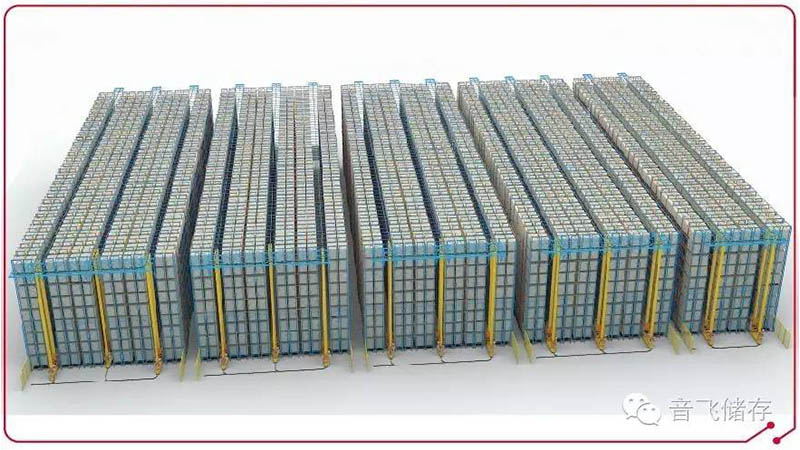

• Adopted automated warehouse system

• Warehouse utilization increased by 200%

Customer Introduction

Ningbo Daqian Textile Co., Ltd. is a subsidiary of Ningbo Shenzhou Knitting Co., Ltd., which is the largest knitting backbone enterprise in the country. Zhejiang Ningbo Shenzhou Knitting Co., Ltd. was founded in March 1990. It is a listed company in Hong Kong. The company covers an area of 68 hectares, with a construction area of 860,000 square meters. It has about 50,000 employees and a total asset of 2.7 billion yuan. With international advanced equipment, it is a large-scale enterprise integrating weaving, dyeing and finishing, printing, embroidery and garment making.

Project Introduction

The cotton yarn warehouse project of Ningbo Daqian Textile Co., Ltd. is located in Beilun District, Ningbo City. The cotton yarn warehouse project of this cooperation will use a pallet load of 700KG, the height of the racking is about 22 meters, and the shuttle racking has 10 layers of goods; A total of 3 stacker cranes and 2 sets of entrance and exit systems. This project greatly reduces production and storage costs and improves production efficiency. The Inform intelligent warehousing solution helps Shenzhou Group realize the intelligent and automated construction of the logistics industry in the process of industrial transformation and upgrading, effectively reducing costs and improving the competitiveness of products.

Inform Storage is committed to providing better solutions for the footwear and garment industry and growing together with customers!

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +86 25 52726370

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: sale@informrack.com