How does ROBOTECH ASRS Breathe New Life into JATCO?

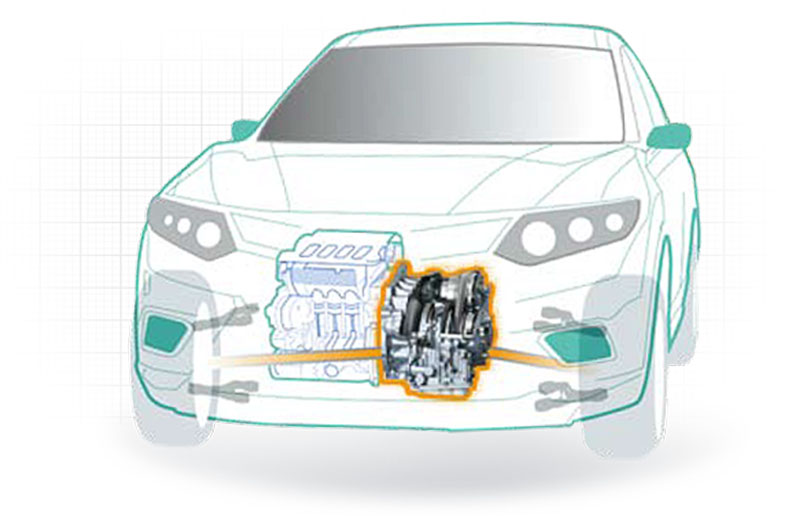

JATCO is one of the three largest automatic transmission manufacturers in the world, with operations in Europe, Asia and the Americas, creating many “world firsts”. Its main products are automatic transmission AT and continuously variable automatic transmission CVT, with a total output of more than 100 million units. Among them, the continuously variable automatic transmission CVT has been produced since 1977, and the cumulative output has exceeded 40 million units, accounting for more than 37% of the global market share, ranking first in the market.

1. Background of the project

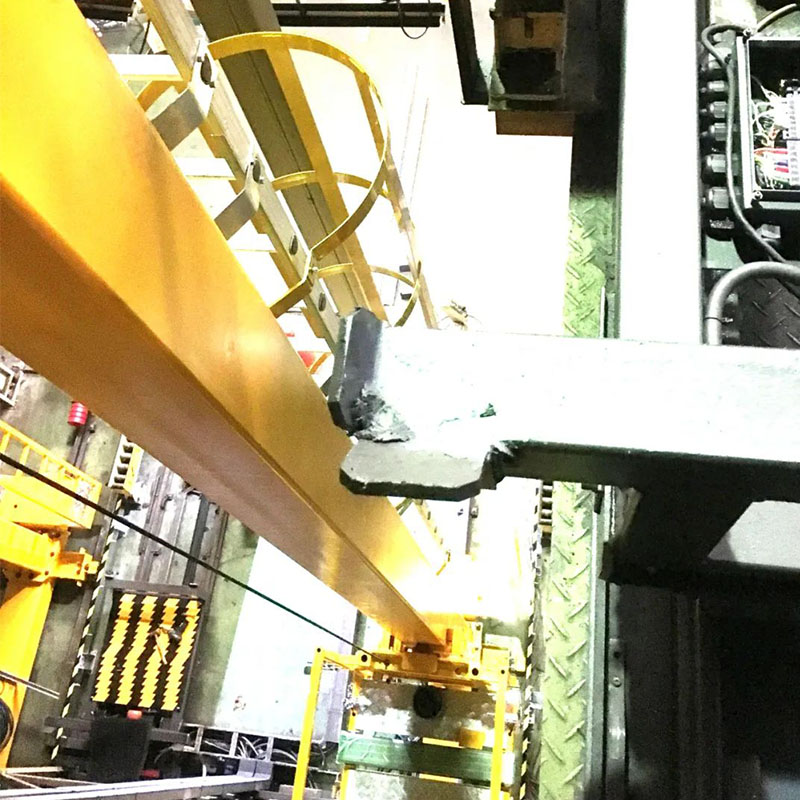

At the beginning of the 21st century, with the development of the automobile industry, the market demand for CVT products with superior environmental performance and dynamic performance continued to expand. In order to meet the production of the factory and its global subsidiaries, JATCO selected a world-leading Japanese local intelligent logistics system integrator to establish an automated logistics center for it. Make it the world’s leading manufacturing enterprise using an intelligent logistics system. As we all know, the overall operation time of stacker crane equipment is around 10-15 years. JATCO hesitated after the device’s useful life expired. Although Japan has a very strong technical strength of automized warehouse automation logistics, it should also take into account the cost performance of products and a perfect service system. ROBOTECH, a Chinese company of European and American descent, makes JATCO shine with its product strength and service concept. After rigorous assessment, the company finally chose to work with ROBOTECH to upgrade the stacker crane equipment.

As we all know, the overall operation time of stacker crane equipment is around 10-15 years. JATCO hesitated after the device’s useful life expired. Although Japan has a very strong technical strength of automized warehouse automation logistics, it should also take into account the cost performance of products and a perfect service system. ROBOTECH, a Chinese company of European and American descent, makes JATCO shine with its product strength and service concept. After rigorous assessment, the company finally chose to work with ROBOTECH to upgrade the stacker crane equipment.

2. ROBOTECH provides solutions

In this scheme, the Automated Warehouse (ASRS) is equipped with 3 double-column stacker crane systems with 1085 pallet positions. Considering the different sizes and complex shapes of JATCO products, the stacker crane selected the most popular star product in the market for automated warehouses – the Panther series. Up to now, this model of ROBOTECH has been iterated to the third-generation new product, which provides the highest degree of high throughput capacity on the basis of long-term continuous operation while adhering to the original high reliability. Compared with similar models, the third-generation Panther model of ROBOTECH operates at a speed of up to 240m/min and has an acceleration of up to 1m/sq.s. These specialized technologies are about 30% higher than the existing domestic standard stacker crane technologies on the market.

Equipment advantage

• High work efficiency, greatly reducing working time;

• High technology integration, good security and high positioning accuracy;

• High-density storage, warehouse utilization is 30% higher than that of traditional automated warehouse storage systems (AS/RS);

• Flexible operation mode;

• The goods can be stored in FIFO and FIFO.

3. ROBOTECH provides services

The challenge of upgrading the old warehouse is not only to ensure the uninterrupted production of the factory, but also to ensure the seamless connection with the original automated warehouse. As a manufacturing enterprise, JATCO has high requirements for customized equipment design. During equipment installation, all spare parts dimensions must ensure zero error. JATCO is very satisfied with the fast and efficient seamless upgrade.

Service system

• Planning and implementation of logistics system equipment

• High degree of customized design of non-standard equipment

• User training

• International projects are highly responsive and equipped with business visas

• Ongoing after-sales service and operational services

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +86 25 52726370

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: sale@informrack.com