- Home

- News

- How does Automated Warehouse Storage Reveal the Optimal Solution of Pharmaceutical Smart Logistics?

How does Automated Warehouse Storage Reveal the Optimal Solution of Pharmaceutical Smart Logistics?

Luyan Pharma ranks No. 16 among the top 100 pharmaceutical wholesale enterprises in China by main business revenue, and has been ranked No. 1 among pharmaceutical distribution enterprises in Fujian Province for 11 consecutive years.

1. Original Pharmaceutical Logistics Process

Due to the particularity of the pharmaceutical market, pharmaceutical distribution companies must not only meet the timeliness and uncertainty of terminal needs, and the urgency of sudden infectious diseases, but also need to deal with the periodicity of pharmaceutical industrial production and the uncertainty of in-transit transportation.

Luyan Pharma hopes to solve the problem of whole package and bulk sorting through forward-looking automated logistics solutions, improve operational efficiency through highly intelligent and automated technical means, while reducing operating costs and achieving economic growth. How did ROBOTECH realize Luyan Pharma’s expectations for Xiamen Modern Pharmaceutical Intelligent Warehousing and Distribution Center?

2. Careful Planning, Breakthroughs One by One

- Pallet warehouse

- Multi-pass warehouse

- Floor warehouse

- In-out warehouse transportation

- Order picking

- Inter-floor transportation

- Goods-to-person picking

- WCS/WMS software system

Challenges:

• There are many categories of drug SKU, and the replenishment process is complicated;

• Traditional manual operations are used in all links, which is inefficient;

• To carry out multi-standard and small-batch order operations in a large area, the operator needs to travel to and from the

designated area on foot, and the operation takes a long time;

• The picking area has a complicated process. Not only does it have to be manually picked and checked according to the

content of the order, but also the products are damaged from time to time, and the picking error rate remains high.

The whole project includes pallet warehouse, multi shuttle warehouse, floor warehouse, in-out warehouse transportation, order picking, inter-floor transportation, goods-to-person picking, WCS/WMS software system, etc.

Pallet Storage Area

The pallet storage area includes 6 lanes and 12 floors. When the palletized goods leave the high-bay warehouse, they will be delivered out of the warehouse or sent to the next link for whole picking, which greatly improves the utilization of storage space.

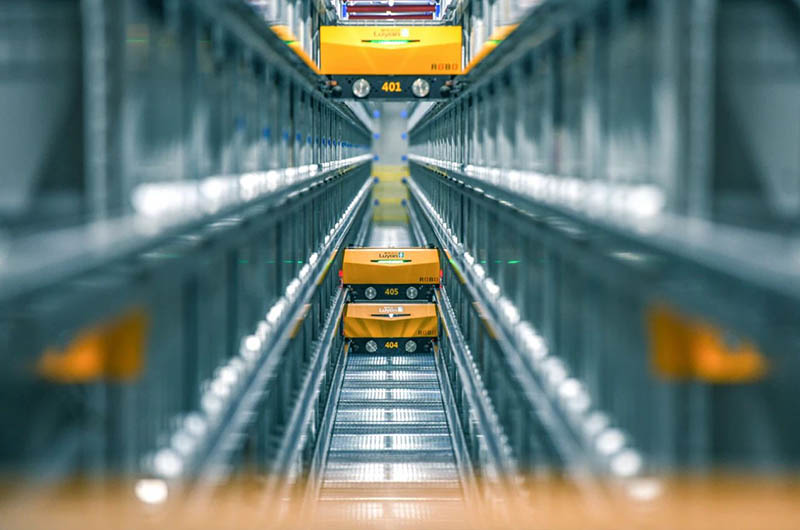

Bin Storage Area

The bin storage area is designed with 4 lanes and 34 floors, with a storage capacity of 2,000 boxes/hour. Compared with traditional manual picking, the multi shuttle system realizes fully automated process operations. Moreover, the system is easy and flexible to operate, and the modular design can be applied to goods of different sizes and weights. By using a multi shuttle system, order picking rates at the company’s central warehouse have increased significantly.

Goods to Person Picking System

The 4 goods-to-person picking stations are ergonomic, and operators can operate in the “golden zone”, and more than 80,000 items are picked every day, which is more than 3 times more efficient than manual picking.

A-Frame Sorter

The A-Frame sorter sorts high-frequency products, replenishes the goods during low peak hours, and is fully used for automatic picking during peak hours, and personnel can optimize the configuration according to warehousing operations.

The A-Frame sorter is suitable for small items, sorting at a rate of 5,000 pieces/hour. Improved picking efficiency and quick picking accuracy.

Huge Cost Advantages:

• The work efficiency is improved, and the picking efficiency can be increased by up to 6 times;

• The accuracy rate can be increased up to 99.999%;

• Operational efficiency is significantly improved by 50%;

• Double warehouse storage performance within existing floor space;

• Modular intelligent expansion can meet longer-term business development.

3. Innovation Creator will Win

Innovative Breakthrough:

• The multi shuttle bin storage is 22 meters high, breaking through the tradition, greatly improving the space utilization rate

of storage, and at the same time ensuring the high positioning accuracy and high reliability of the system;

• Goods-to-person selection to avoid the phenomenon of people waiting for goods.

• Each picking station is equipped with an empty box buffer, which can quickly replenish and shorten the time for people to wait for

order boxes.

• ”Reservoir” design. The intelligent system automatically calculates the supply sequence of the bins, and under the WCS

scheduling, the bins are supplied in the optimized sequence.

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +86 25 52726370

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: sale@informrack.com