Advantages of Four Way Shuttle Application in the Liquor Industry

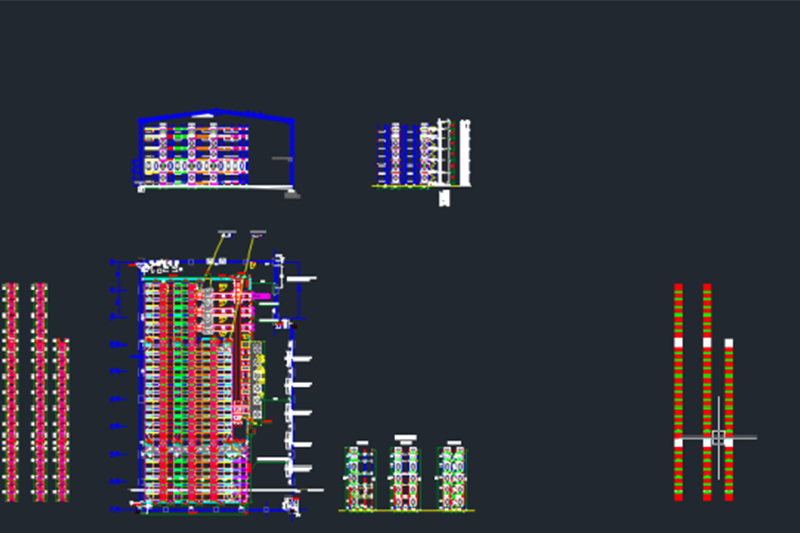

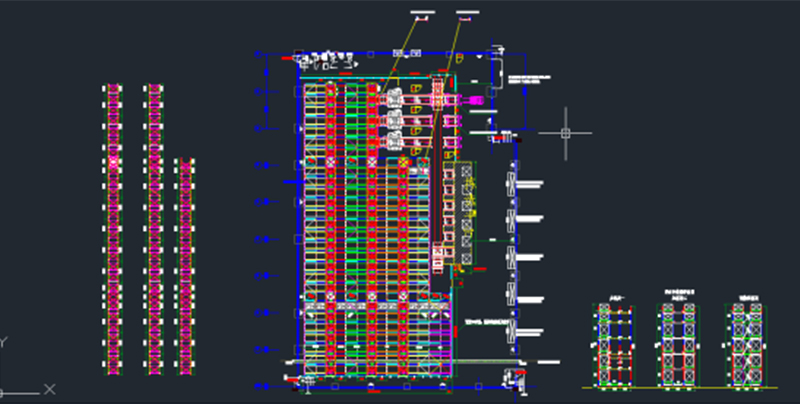

1.Project overview

– Pallet size 1200 * 1200 * 1600mm

– 1T

– A total of 1260 pallets

– 6 levels, with one four-way shuttle per level, a total of 6 four-way shuttles

– 3 lifters

– 1 RGV

Layout

2.Features

The four-way radio shuttle system can be well adapted to special application environments such as low warehouses and irregular shapes, and can meet operation scenarios such as large changes in the efficiency of in and out operations and high efficiency requirements.

Four-way radio shuttle has remarkable features:

1) The four-way radio shuttle has compact structure, small height and size, saving more storage space;

2) Four-way running: Realize one-stop point-to-point transportation, which can reach any cargo space on the plane level of the warehouse;

3) Smart level change: With the lifter, the four-way radio shuttle can realize the efficient working mode of automatic and precise layer changing;

4) Intelligent control: It has two working modes of automatic and semi-automatic;

5) High storage space utilization: Compared with the ordinary shuttle racking system, the four-way radio shuttle-type automatic intensive storage system can further improve the utilization rate of storage space, usually by 20% to 30%, which is 2 to 5 times that of the ordinary flat warehouse;

6) Dynamic management of cargo space: As an advanced automatic material handling equipment, the four-way radio shuttle can not only enable the goods to be automatically stored and stored in the warehouse according to the needs, but also can be organically connected with the production links outside the warehouse.

7) Unmanned automatic warehousing mode: It greatly reduces the workload of warehouse staff and provides the possibility for the warehouse to realize unmanned work.

Features of Inform storage four-way radio shuttle:

○ Independent integrated circuit board technology;

○ Advanced communication technology;

○ run in four directions and work across lanes;

○ Unique design, level change operation;

○ Multi vehicles collaborative operation on the same level;

○ Assist in intelligent scheduling and path planning;

○ Fleet operations are not limited to first-in first-out (FIFO) or first-in-last-out (FILO) warehousing operations.

3.Project highlights

▪ Empty pallets are depalletized, automatically sequenced and the supply production line;

▪ After leaving the warehouse, the empty pallets are returned to the warehouse;

▪ Automatic inventory;

▪ The final goods are gathered onto pallet and put into the warehouse;

▪ Over-sized pallets in and out of the warehouse;

▪ The utilization rate of warehouse space is increased by 50%, and the labor is reduced by 50%.

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +8613636391926 / +86 13851666948

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: lhm@informrack.com

kevin@informrack.com