- Home

- News

- The First China Federation of Things Storage Technology Annual Conference was Held in Huzhou, and Inform Storage was Invited to Participate

The First China Federation of Things Storage Technology Annual Conference was Held in Huzhou, and Inform Storage was Invited to Participate

From May 26th to 27th, the first China Federation of Things Storage Technology Annual Conference was held in Huzhou, Zhejiang, and Inform Storage was invited to participate.

The conference focused on the transformation and upgrading of digital warehousing, the construction of intelligent warehouses, value-added service of warehousing enterprises, and the transformation of “digital factory” warehousing enterprises, and conducted in-depth exchanges and discussions with government departments, industry leaders, college experts, and enterprise representatives.

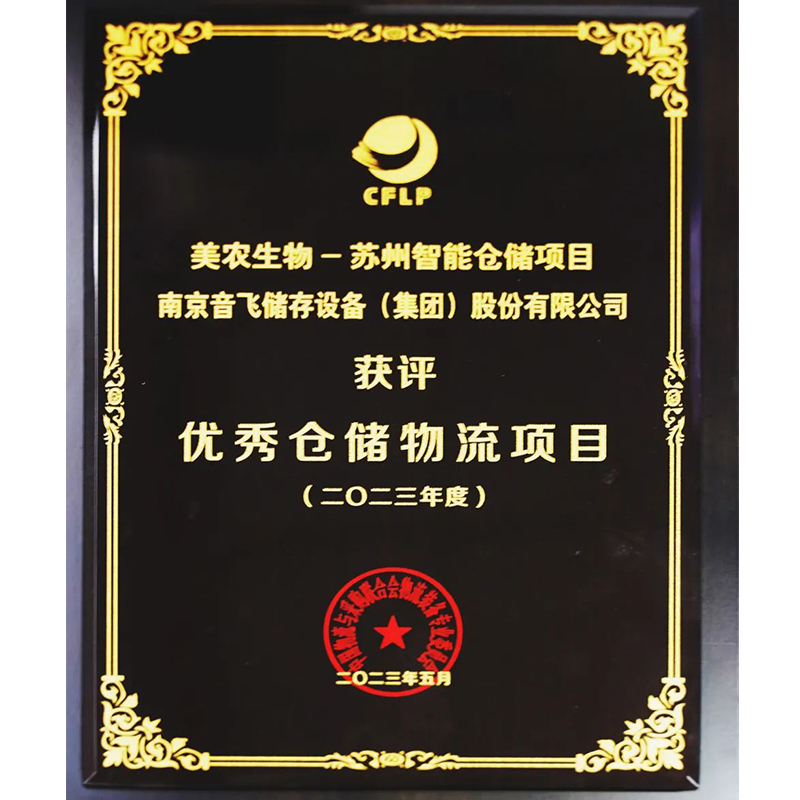

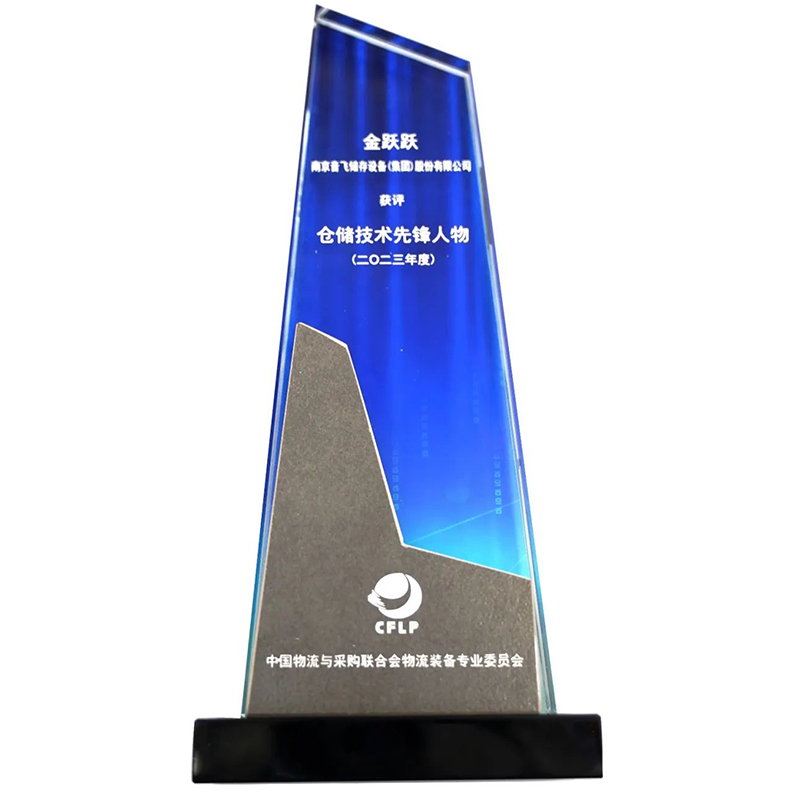

At this conference, Inform Storage won the “2023 Excellent Warehousing and Logistics Project Award” for its Suzhou Meinong Smart Warehousing Project. Jin Yueyue, General Manager of Inform Storage, has won the individual honor of “Warehouse Technology Pioneer Award”. There are a total of 2 awards, which truly deserve it.

Excellent Warehouse Logistics Project Award

Excellent Warehouse Logistics Project Award

Warehouse Technology Pioneer Award

Warehouse Technology Pioneer Award

1. Project overview

- Four-way radio shuttle vehicle dense storage system

– Height of 12 meters and 6 floors

– Totaling 3201 cargo spaces

– 6 four-way radio shuttles

– 2 vertical conveyors

– WCS warehouse monitoring system

– WMS warehouse management system

– One four-way radio shuttle

Inform Storage is a four-way radio shuttle vehicle dense storage system created by Meinong Biotechnology, with a height of 12 meters and 6 floors, totaling 3201 cargo spaces. It is equipped with 6 four-way radio shuttles, 2 vertical conveyors, WCS warehouse monitoring system, and WMS warehouse management system. Each layer is equipped with one four-way radio shuttle, which can work together with multiple machines on the same layer or change layers through a lifting machine.

2. System advantages

1) Low requirements for warehouse height, area, regularity, etc

2) High density storage, flexible design of cargo space depth

3) Strong flexibility in emergency

4) Modular design with good scalability, increasing the number of shuttles according to different efficiencies

3. Customer benefits

The dense warehouse system can achieve 24-hour fully automated batch pallet operations, with a storage capacity increase of 30% -70% compared to before, a storage space utilization rate of up to 95%, doubled work efficiency, and greatly saved labor costs. At the same time, it can achieve digital and visual storage system management, and achieve lean management of enterprises.

In the future, Inform Storage will continue to deepen industry scenario application research and provide more high-quality products and services; Continuously improving customer satisfaction and promoting continuous innovation and development in the industry.

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +8613636391926 / +86 13851666948

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: lhm@informrack.com