- Home

- News

- How does the Inform Intelligent Storage Project Help to Upgrade the Digital Intelligence of “MENON”?

How does the Inform Intelligent Storage Project Help to Upgrade the Digital Intelligence of “MENON”?

Recently, the “Suzhou MENON” smart storage project jointly built by Inform Storage and MENON was officially put into operation. As a “benchmark project” of MENON, the completion of MENON in Suzhou is a milestone for MENON. After it is officially put into production, it will further promote the implementation of MENON’s product strategy of “seed and product separation” and help it realize its “doubling plan” as soon as possible.

As the world’s leading logistics equipment manufacturer and the leading enterprise in the field of intelligent logistics, Inform Storage has been deeply involved in the industry for many years, with more than 20000 successful project cases. Its business covers intelligent logistics robots, intelligent software, system integration, warehousing and operation services, and can provide customers with one-stop intelligent logistics warehousing system solutions.

After the strategic cooperation between the two parties was reached, Sonic Fly Storage and MENON Biotech understood the needs through several rounds of negotiation, and carried out multi-dimensional system analysis on the project positioning in Suzhou and its industry characteristics, application scenarios, product characteristics, etc. Finally, the four-way radio shuttle system solution was adopted to carry out the overall planning, design and implementation of the project.

1. Project introduction

MENON (stock code: 301156) was founded in 1997. It is a high-tech enterprise specializing in the research, development, production and sales of feed additives and enzymolysis protein feed raw materials. The company’s products are mainly used in animal feed such as pigs, poultry, ruminants and aquatic products, and is committed to “becoming a leading animal nutrition technology company in the world”.

The Suzhou MENON Project covers an area of about 20000 square meters and has seven independent production lines, mainly engaged in the research, development and large-scale production of acidifiers, ruminants, etc. The completed Suzhou MENON meets the requirements of environmental protection, waste treatment and emission, safe production, energy conservation and consumption reduction, and is building towards automation, digitalization and intelligence, including intelligent storage system, automatic label station, full-automatic packaging line, robot feeding station, visual digital control center, etc.

2. Solution

– Four-way radio shuttle intensive warehouse system

– 12 meters high and 6 floors high

– 3201 cargo spaces

– 6 four-way radio shuttles

– 2 vertical conveyors

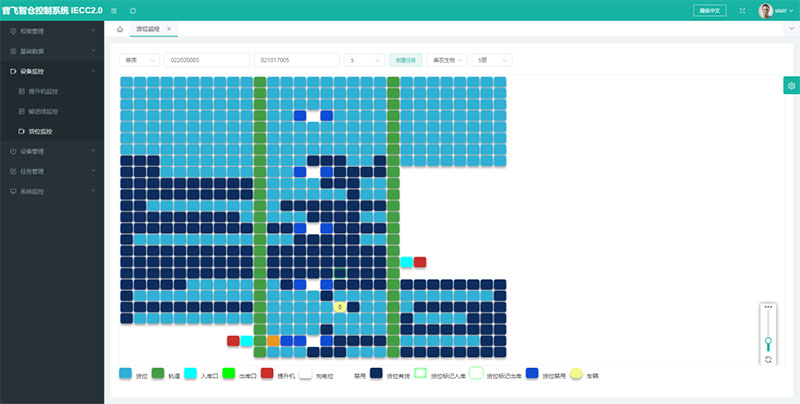

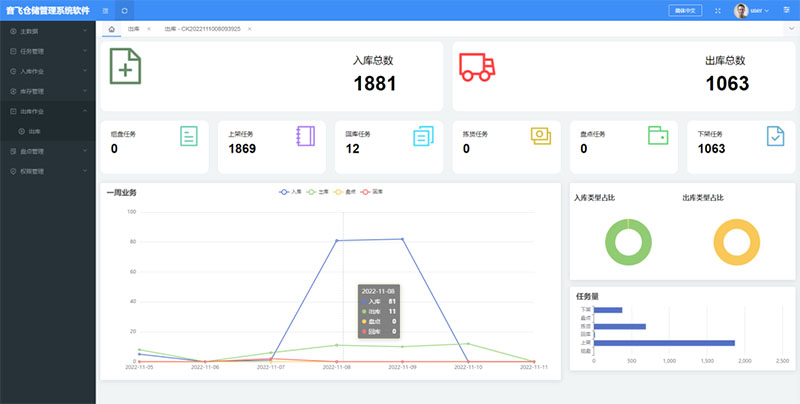

– WCS storage monitoring system & WMS storage management system

– A four-way radio shuttle

– Multiple vehicles & lifter

The four-way radio shuttle intensive warehouse system built by Inform Storage for MENON is 12 meters high and 6 floors high, with a total of 3201 cargo spaces. It is equipped with 6 four-way radio shuttles, 2 vertical conveyors, WCS storage monitoring system and WMS storage management system. Each floor is equipped with a four-way radio shuttle, which can work together with multiple vehicles on the same floor, and can also realize layer change operation through the lifter.

Through WMS/WCS intelligent warehousing software, the whole process digital, intelligent warehousing management and visual management can be realized. In an emergency state, the customer can also realize the warehousing and unloading operation through the WCS system or the on-site ECS system operation screen.

3. System advantages

1). The requirements for warehouse height, area and regularity are not high;

2). High density storage, flexible design of cargo space depth;

3). Strong flexibility in emergency;

4). Modular design, good scalability, increase the number of radio shuttles according to different efficiency;

4. Value for customers

– 24-hour fully automated batch pallet operation

– Storage capacity increased by 30% – 70%

– Storage space utilization rate up to 95%

The dense warehouse system can realize 24-hour fully automated batch pallet operation, with storage capacity increased by 30% – 70% compared with the previous one, storage space utilization rate up to 95%, operation efficiency doubled, and labor cost greatly saved.

In the future, Inform Storage will continue to drive innovation, optimize product structure, create differentiation advantages, improve customer service satisfaction, and make more contributions to the development of China’s smart logistics industry.

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +86 13851666948

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: kevin@informrack.com