- Home

- News

- Smart Voyage, Building the Future Together | Opening a New Chapter in Cold Chain Logistics

Smart Voyage, Building the Future Together | Opening a New Chapter in Cold Chain Logistics

With the rapid development of the food and beverage industry and the increasing demands for food safety and quality from consumers, central kitchens have become an essential link in centralized procurement, processing, and distribution, with their significance growing ever more prominent.

Leveraging its expertise in logistics automation and warehouse management, Inform Storage was responsible for the entire project’s design, installation, commissioning, packaging of goods, and transportation, as well as the compilation of operation and maintenance manuals.

The automated equipment in this project is primarily divided into three parts: the automated stacker system in Warehouse A, the four-way shuttle system in Warehouse B, and the AGV forklift system in Warehouse A.

The automated stacker system in Warehouse A is equipped with one single-deep straight-rail stacker and one double-deep straight-rail stacker, totaling 1,535 storage positions. The system consists of an automated storage and retrieval system (AS/RS) and a multi-level warehouse. AGV forklifts are used on the first floor of Warehouse A for inbound transportation operations.

To ensure the safety of the stackers, operators, and goods, Inform Storage has equipped the stackers with several safety features: forced deceleration protection, terminal stop protection, horizontal travel limit protection, forced deceleration for lifting, lifting travel limit protection, pallet deviation detection, real and virtual position detection, fork extension torque limit protection, electrical interlock protection, emergency stop, and more.

The four-way shuttle system in Warehouse B is a cold storage system equipped with 13 four-way shuttles, 5 lifts, and a total of 4,340 storage positions. Structurally, it consists of an AS/RS and a multi-level warehouse spanning from the first to the fourth floor. Functionally, it is divided into the front warehouse operation area and the rear cold storage area. The front warehouse operation area is used for receiving and dispatching goods, “goods-to-person” picking, and box sorting operations with temperatures between 0-4°C.

The front warehouse operation area on the first floor is for receiving and dispatching goods with temperatures maintained at 0-4°C. The second floor is for “goods-to-person” picking and box sorting, also at 0-4°C. The third and fourth floors are reserved for ambient temperature operations. The rear cold storage area has three cold rooms: the first and third cold rooms are freezer storage with temperatures ranging from -25 to -18°C, while the second cold room serves as a combined refrigeration/freezing space with temperatures ranging from -25 to 10°C.

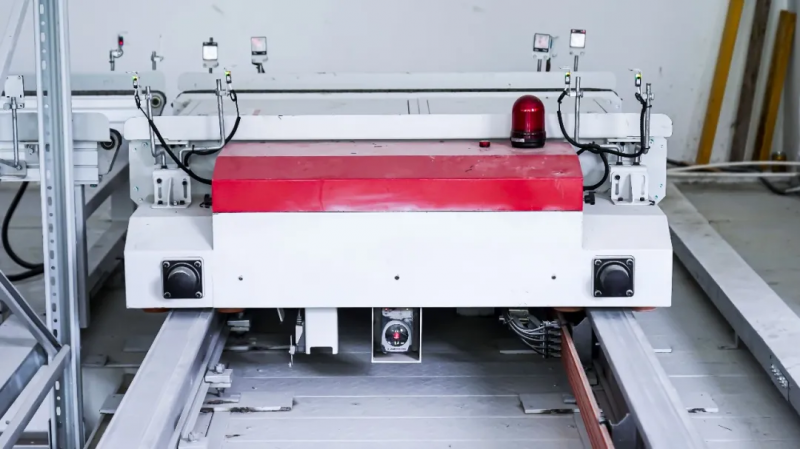

The four-way pallet shuttle is an intelligent device designed for transporting palletized goods. It can move both longitudinally and laterally, allowing it to reach any position in the warehouse. The horizontal movement and retrieval of goods within the racks are handled by a single four-way shuttle. By using a lift to change floors, the automation level of the system is greatly enhanced, making it the latest generation of intelligent handling equipment for high-density pallet storage solutions.

The vertical conveyor is a crucial piece of equipment for vertical movement in the four-way shuttle system. It is mainly used for storing and retrieving goods on different floors and for the four-way shuttle’s floor-changing operations.

The RGV (Rail Guided Vehicle) operates on a dual-rail four-wheel system, with laser-guided navigation for positioning. It is generally used for transferring goods between conveyor lines. The control system relies on laser positioning for precise shuttle location management. Its modular design allows it to adapt to various needs. The support structure of the conveyors uses specialized structural beams, making installation more flexible and convenient.

As a key part of our intelligent cold chain logistics strategy, the central kitchen project aims to create a modern food processing center that integrates agricultural product processing, cold chain storage, and smart distribution.

Since the project’s inception, it has garnered widespread attention and support from local government and various sectors of society. We have successfully achieved end-to-end intelligent management, from raw material procurement to finished product dispatch, ensuring food safety and freshness. The project has significantly contributed to local economic development and supported rural revitalization efforts.

Inform remains committed to its development philosophy of “customer-centric and value-driven,” deepening its focus on cold chain logistics and food processing. We will continue to drive technological innovation and product upgrades. Using the central kitchen project as a new starting point, we aim to further expand our market presence and strengthen cooperation with upstream and downstream enterprises in the supply chain, jointly building an intelligent, efficient, and green cold chain logistics system!