- Home

- News

- ROBOTECH: Innovating Heavy-duty Stacker Crane Technology and Solutions Based on Demand(Part 1)

ROBOTECH: Innovating Heavy-duty Stacker Crane Technology and Solutions Based on Demand(Part 1)

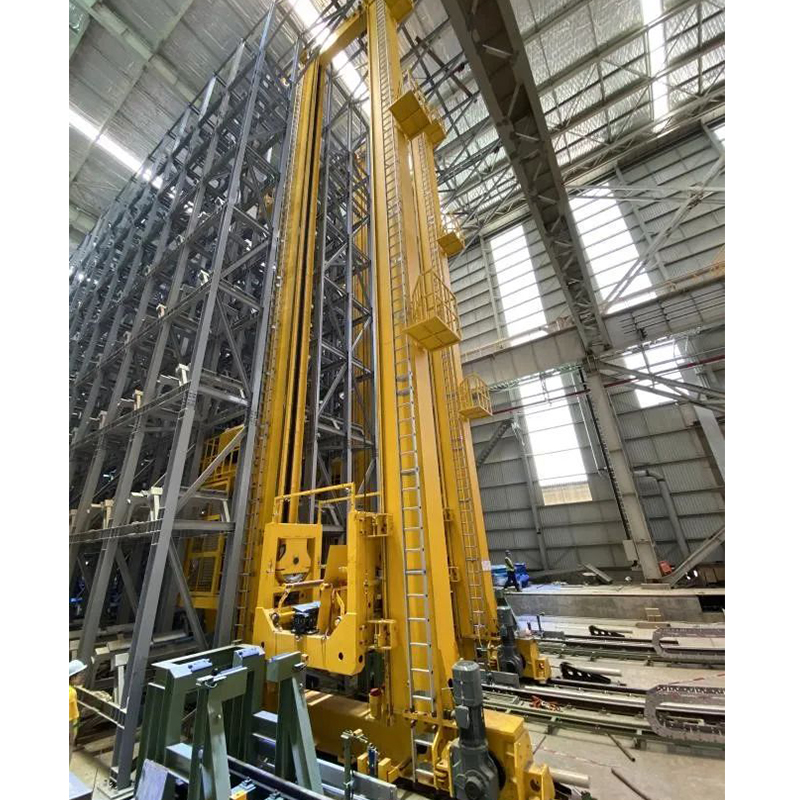

ROBOTECH is committed to developing stacker crane products, supporting conveyor products, automated warehouse management system software and other products, and its business covers many industries. Its team can also customize non-standard designs for customers based on the specifications of the goods. Among them, the “Bull” series stacker crane is specially developed and designed for heavy load logistics, which can efficiently and stably meet the automated access requirements of heavy cargo.

Zhou Weicun, Director of the Second Engineering Technology Center of ROBOTECH Automation Technology (Suzhou) Co., Ltd

Zhou Weicun, Director of the Second Engineering Technology Center of ROBOTECH Automation Technology (Suzhou) Co., Ltd

Recently, a journalist for logistics technology and application interviewed Mr. Zhou Weicun, Director of the Second Engineering Technology Center of ROBOTECH Automation Technology (Suzhou) Co., Ltd., and asked him to introduce the characteristics, related technologies and solutions, and future development trends of heavy load logistics.

Reporter: How does the industry define “heavy load logistics“? What are the corresponding products of ROBOTECH?

Zhou Weicun: Currently, there is no clear definition of “heavy load logistics” in the industry. Internationally, for load standards, we can combine them with the European pallet standard UIC 435 to simply classify light and heavy goods. For example, standard pallets placed irregularly on pallets can carry 1000kg of ordinary goods, regular and flat pallets can carry 1500kg, and compact and regular pallets can carry 2000kg.

With the rapid development of the logistics industry, the demand for warehouse automation and intelligence in various industries is increasing day by day. Depending on the weight and size of the goods, the handling and storage equipment used may vary, and the structural design and component requirements for logistics equipment may also vary. When logistics equipment suppliers conduct system planning, they will conduct corresponding equipment research and development design based on different planning access schemes.

ROBOTECH’s stacker crane products help upgrade heavy load logistics automation

ROBOTECH’s stacker crane products help upgrade heavy load logistics automation

The stacker crane is a flagship product of ROBOTECH. Currently, it has seven series of products: “Zebra“, “Cheetah“, “Lion“, “Panther“, “Giraffe“, “Bull“, and “Flying Fish“. Among them, the “Bull” series stacker crane is specially developed and designed for heavy load logistics, with a load capacity range of 5t to 30t, which can efficiently and stably meet the automated access requirements of heavy cargo. When the material quality exceeds the bearing range of 30t, the ROBOTECH Austria R&D Center can customize non-standard designs for customers based on the specifications of the goods.

Reporter: What are the special requirements for heavy load logistics for stacker crane equipment?

Zhou Weicun: Usually, when the weight of goods is too large, there are high requirements for the metal structure, loading platform, and forks of the stacker crane, making the design more difficult. The specific characteristics and requirements are as follows:

1). Materials. Compared to light load stacker cranes, heavy load equipment has a larger overall mass, and the overall steel structure design requires the use of high-performance material components.

2). Structure. When the height and weight of the stacker crane are large, the column needs to be assembled and welded with steel plates. Flat steel guide rails or T-shaped guide rails need to be welded on the column. After the main steel structure is welded, stress relief treatment needs to be carried out; The lifting transmission mechanism is designed with multiple sets of movable pulleys to reduce the force on the steel wire rope, reduce the extension of the steel wire rope, and increase the service life of the steel wire rope; When designing, it is possible to consider adding a wire rope anti shaking device based on the height of the equipment.

3). Safety. When selecting models, the safety of heavy load equipment should be taken into consideration, and a customized design of the clamping mechanism is needed to use greater braking force to brake the clamp body and column guide rail; and choose a suitable heavy-duty hydraulic buffer device. In electrical design, dual drive synchronization and anti shake control are adopted to ensure efficient and stable operation of the equipment; Use functions such as automatic address recognition and collision avoidance to improve the safety of equipment handling and storage.

4). Energy consumption. Compared to light load equipment, the motor power of heavy-duty stacker cranes is higher, and the drive power is also significantly increased, which requires greater energy conservation; At present, our equipment energy consumption level can reach IE4 level (corresponding to the new national standard level 2 energy efficiency level).

Reporter: Based on the above special requirements, what key issues need to be paid attention to when planning and designing automated heavy load logistics solutions mainly based on stacker cranes?

Zhou Weicun: In an automated heavy load logistics system, it mainly consists of core intelligent equipment such as heavy-duty rackings, heavy-duty stacker cranes, heavy-duty conveyor lines, RGVs, and warehousing intelligent system management software. To ensure stable, reliable, and efficient operation of the system while bearing a large load, high requirements are placed on the structural strength, manufacturing accuracy, and overall performance of software and hardware equipment such as rackings and stacker cranes. Generally, equipment suppliers often find it difficult to solve related problems when entering the field of heavy loads.

Compared to lightweight equipment, heavy-duty stacker cranes have higher manufacturing and installation costs

Compared to lightweight equipment, heavy-duty stacker cranes have higher manufacturing and installation costs

For example, in the design of heavy-duty stacker cranes, compared to light loads, due to factors such as weight and volume, heavy-duty equipment needs to have high load-bearing capacity while also meeting high operating speed and accuracy. When allocating storage space, it is necessary to allocate the partition of goods in the rackings reasonably to reduce the concentration of goods on the rackings and ground caused by too dense storage.

In the manufacturing and production process of heavy-duty models, it is necessary to process the column guide rail, which requires high machining accuracy. Especially when the equipment height is high, the welding deviation of the guide rail can cause serious wear and tear of the guide wheel during use. During the transportation process, longer columns may have certain requirements for the transportation equipment. If the specifications of heavy-duty materials are large, a larger space is needed for storage. During loading and unloading, larger lifting equipment is required, and heavy-duty equipment also needs to remove the guide wheel before reinstalling, which requires higher manufacturing and installation costs compared to light load models.

In the manufacturing and production process of heavy-duty models, it is necessary to process the column guide rail, which requires high machining accuracy. Especially when the equipment height is high, the welding deviation of the guide rail can cause serious wear and tear of the guide wheel during use. During the transportation process, longer columns may have certain requirements for the transportation equipment. If the specifications of heavy-duty materials are large, a larger space is needed for storage. During loading and unloading, larger lifting equipment is required, and heavy-duty equipment also needs to remove the guide wheel before reinstalling, which requires higher manufacturing and installation costs compared to light load models.

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +8613636391926 / +86 13851666948

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: lhm@informrack.com