- Home

- News

- How Inform Four-way Radio Shuttle System Solution Build Intelligent and Efficient Warehousing and Logistics?

How Inform Four-way Radio Shuttle System Solution Build Intelligent and Efficient Warehousing and Logistics?

1. Customer Introduction

Tianjin Dongda Chemical Group Co., Ltd was established in March 2, 1998. It is a professional food additives manufacturing enterprise which specializes in research and development, production and sales. The factory covers an area of 100 thousands square meters.

2. Project Overview

- 1,506 pallet positions

- Three Four-way Radio Shuttles

- Two reciprocating elevators

- 24-hour unmanned operation

- 40 pallets per hour

This project uses Four-way Radio Shuttle compact storage system to store goods, including 1,506 pallet positions. Three Four-way Radio Shuttles and two reciprocating elevators are planned to cooperate with the production line to achieve 24-hour unmanned operation. Using various conveying systems such as RGV, it can meet the business processes such as automatic inventory, abnormal in and out of storage, empty pallets in storage, and dismantling and sending them to the production line. The Four-way Radio Shuttle can work with multiple units on the same floor, with a maximum efficiency of more than 40 pallets per hour. One set of WMS and WCS software systems are planned, which mainly store chemical finished products.

In this project, from the production line to the inventory, seamless connection is achieved to meet the needs of customers for production and storage according to orders.

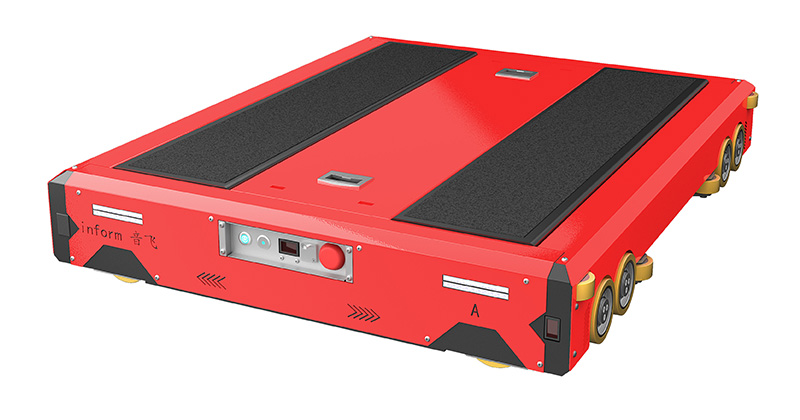

3. Four-way Radio Shuttle

The Four-way Radio Shuttle is an intelligent device used for palletized goods handling, which can realize vertical and horizontal running, and can reach any position in the warehouse through the racking rails. The horizontal movement and storage of goods in the racking are completed by only one Four-way Radio Shuttle. Changing layers by the elevator, the degree of automation of the system is greatly improved. It is the latest generation of intelligent handling equipment for pallet-type compact storage solutions.

Safety assistance:

▪ Sensor design, pallets can be accurately detected for handling;

▪ Laser limit technology to ensure the safety of shuttles and goods;

▪ Rail lock, the shuttle only runs on the rails, which is safe and reliable;

▪ Anti-skid design of pallet;

▪ Laser ranging, early warning, multi-level speed and position control;

▪ Dynamic location detection, real-time traffic safety guarantee.

Features of product:

▪ Innovative non-hydraulic reversing and lifting mechanism;

▪ Self-developed third-generation integrated circuit control system ECS that fully integrates energy modules, control

modules, communication modules, and data acquisition modules;

▪ Support multi-vehicle operation on the same layer, with self-detection and self-obstacle avoidance capability;

▪ Support multi size of pallets mixing;

▪ Support operation and maintenance data collection and analysis;

▪ Four-way running, working across roadways and layers;

▪ Location awareness, assist WCS intelligent scheduling and route control;

▪ Agility, flexible and highly expandable.

Features of Four-way Radio Shuttle System:

▪ Independent integrated circuit board technology to support data collection and platform display;

▪ Support multi size of pallets mixing;

▪ Four-way running, working across roadways and layers;

▪ Support multi-vehicle cooperative operation on the same layer, with self-detection and self-obstacle avoidance

capability;

▪ Location awareness, assist WCS intelligent scheduling and path planning;

▪ Fleet operations are not limited to first-in and first-out (FIFO) or first-in and last-out (FILO) in-out operations;

▪ Agility, flexible and easy to expand.

The system is widely used in cold chain food, textile, chemical, military, automobile and other industries, which can improve the efficiency of storage operations, reduce operating costs, and maximize space utilization.

4. Project Highlights

▪ Empty pallets are depalletized, automatically sequenced and the supply production line

▪ After leaving the warehouse, the empty pallets are returned to the warehouse;

▪ Automatic inventory;

▪ The final goods are gathered onto pallet and put into the warehouse;

▪ Over-sized pallets in and out of the warehouse;

▪ The utilization rate of warehouse space is increased by 50%, and the labor is reduced by 50%.

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +86 25 52726370

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: sale@informrack.com