How can Four-way Radio Shuttle System Contribute to the Chemical Industry?

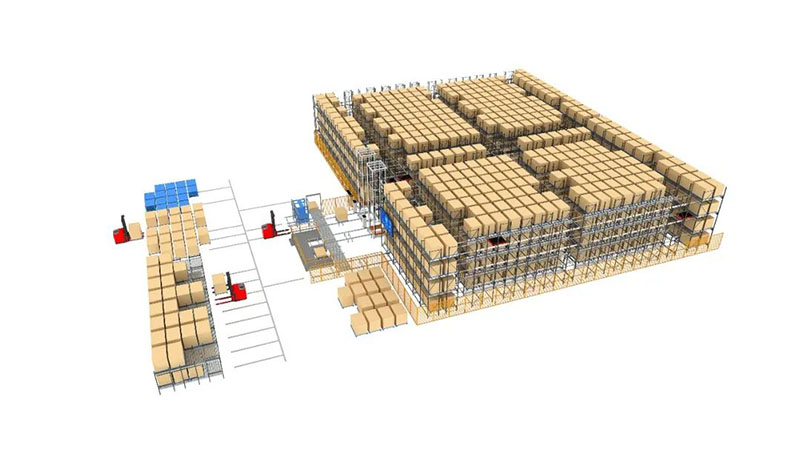

Inform storage four-way radio shuttle system is usually composed of four-way radio shuttle, elevator, conveyor or AGV, dense storage rack and WMS, WCS system, it is the latest generation of intelligent dense storage solution.

The system adopts modular design, strong flexibility, high expandability and easy maintenance. It is suitable not only for low-traffic, high-density storage, but also for high-traffic, high-density storage; the overall efficiency can be doubled, and the storage space utilization rate can be as high as 95%.

• System advantage

• System advantage

1. The requirements for the height, area and regularity of the warehouse are not high;

2. High-density storage, flexible design of cargo space depth;

3. Strong flexibility in emergency situations;

4. Modular design, good scalability, increase the number of shuttles according to different efficiencies;

• Solve problems

Pallet storage mode, low storage space utilization and low storage efficiency;

• Efficiency value

It can realize 24-hour fully automated batch pallet operations, increase the storage capacity by 30%-70%, the storage space utilization rate can be as high as 95%, and the operation efficiency is doubled.

• Application scenarios

Palletized cargo storage and heavy cargo storage;

• Applicable industries

Chemicals, new energy vehicles, industrial manufacturing, electrical equipment, alcohol, etc.;

• Project cases

COSMOS Chemical Co. , Ltd., as one of the chemical industry enterprises, the business scope includes the research and development, production and sales of daily chemical raw materials; Products cover cosmetic active ingredients and their raw materials, synthetic fragrances, etc.; It has advanced process technology and research and development technology in related fields; the market covers Europe and the United States, and the main products occupy a large market share of similar products.

In the face of the rapid development of the company and the increasing business volume, the original warehouse management system of COSMOS Chemical has gradually failed to keep up with the needs of the situation, and the digital and intelligent upgrade of production and warehousing is imminent.

As one of the well-known intelligent logistics equipment companies in China, Inform Storage has a number of smart warehousing project cases in the chemical industry. In response to the warehousing application scenario of COSMOS Chemical, Inform Storage planned and designed a four-way radio shuttle system for it, as one of the overall warehousing system solutions for its Maanshan production base.

– Empty bucket four-way radio shuttle intensive warehouse storage systems

– Raw material four-way radio shuttle intensive warehouse storage systems

– 2 main aisles & 1 main aisle

– 2 four-way radio shuttles & 2 four-way radio shuttles

– 2 lifting conveyors & 1 shuttle vertical conveyor

– 372 & 450

According to customer needs and application scenarios, 2 sets of four-way radio shuttle intensive warehouse storage systems are designed, which are empty bucket four-way radio shuttle intensive warehouse storage systems. The number of layers is 2, the empty barrel dense warehouse has 2 main aisles, 2 four-way radio shuttles, 2 lifting conveyors, and the lifting conveyor can realize layer-changing operation. The total storage space of the intensive warehouse is 372.

Raw material four-way radio shuttle intensive warehouse storage systems. The number of layers is 10, the raw material intensive warehouse has 1 main aisle, 2 four-way radio shuttles, 1 shuttle vertical conveyor, and the shuttle vertical conveyor can realize layer-changing operation. The total storage space of the intensive warehouse is 450.

In addition, plan and design a set of stacker crane automated warehouse. The stacker crane automated warehouse has 10 layers. The overall planning is 2 double-deep stacker cranes, and one stacker crane for each aisle. The stacker crane warehouse has a total of 1,500 cargo spaces.

There are many highlights of the project, including the 10-story stacker crane intensive warehouse and the four-way radio shuttle intensive warehouse to achieve seamless multi-floor connection. Intensive warehouses are difficult to install and require high adjustment accuracy, but at the same time fully demonstrate the integration and implementation strength of Inform storage; The raw material four-way radio shuttle intensive warehouse is connected to the explosion-proof workshop for customer operations. Electric cabinets, hoists and corridor RGVs are powered by explosion-proof motors and drag chains.

In addition, the overall warehousing system is equipped with WMS/WCS system intelligent warehousing software, which realizes the whole process automation, digitization, intelligent warehousing and warehouse management and visual management; In an emergency state, the customer can realize the in-out operation through the WCS system or the on-site ECS system operation screen (the in-out and out-of-stock information needs to be supplemented).

NanJing Inform Storage Equipment (Group) Co.,Ltd

Mobile phone: +86 13851666948

Address: No. 470, Yinhua Street, Jiangning District,Nanjing Ctiy,China 211102

Website: www.informrack.com

Email: kevin@informrack.com